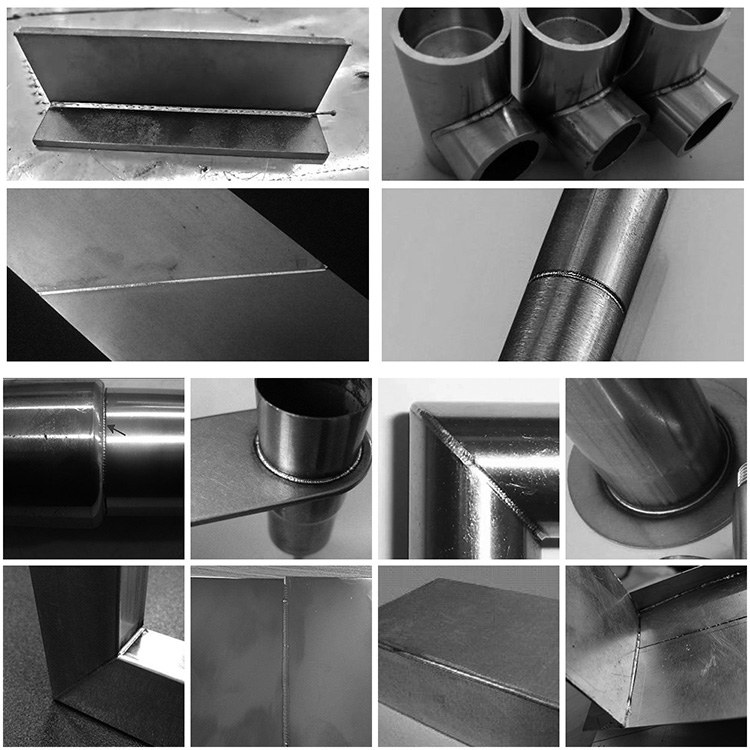

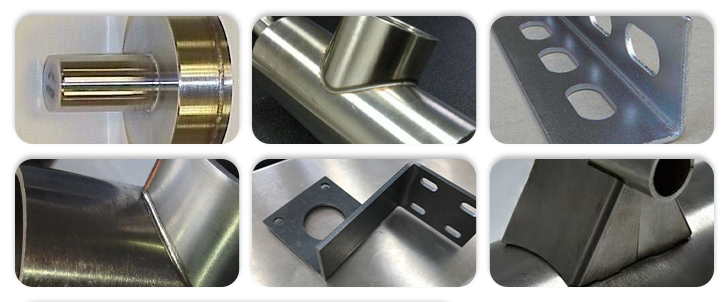

応用

Laser welding is a new welding method, which is widely used in precision processing industries such as automobile industry, metal processing industry, ship and aircraft manufacturing, Furniture and kitchenware processing, electronic products processing, metal parts maintenance, etc. It is mainly aimed at the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, overlap welding and seal welding. Laser welding machines for titanium alloy, galvanized sheet, aluminum material and copper material can accurately weld

Right angle welding sample Tube Arc welding Irregular seam welding

レーザー溶接の利点

1.溶接中に接触せずに損傷または亀裂が発生しやすく、溶接対象物に機械的応力を発生させない他のコンポーネントを溶接できます。

2. It can irradiate the narrow parts that cannot be accessed by the soldering iron head on the circuit with dense components and change the angle when there is no distance between adjacent components in dense assembly, without heating the whole circuit board

3.溶接中、溶接領域のみが局所的に加熱され、他の非溶接領域は熱の影響を受けません。

4. The welding time is short, the efficiency is high, and the solder joint will not form a thick intermetallic layer, so the quality is reliable

5.高い保守性。従来の電気はんだごて溶接でははんだごてヘッドを定期的に交換する必要がありますが、レーザー溶接では付属品をごくわずかしか交換する必要がないため、メンテナンスコストを削減できます。

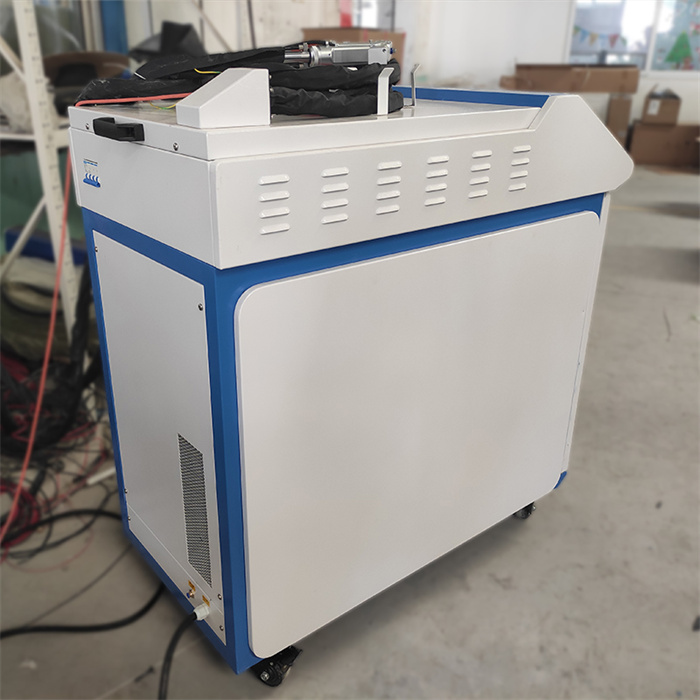

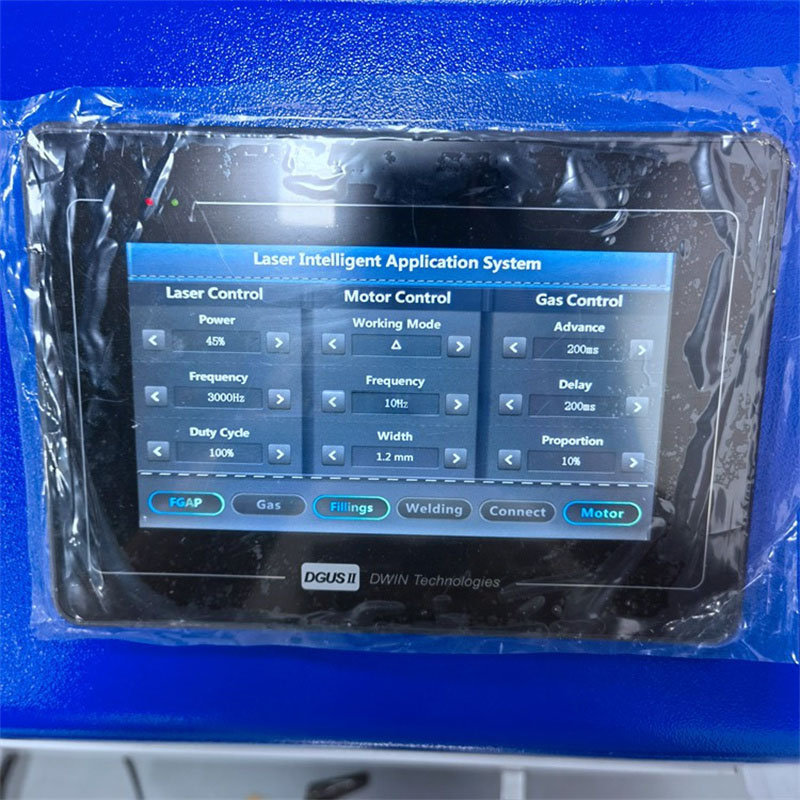

構成

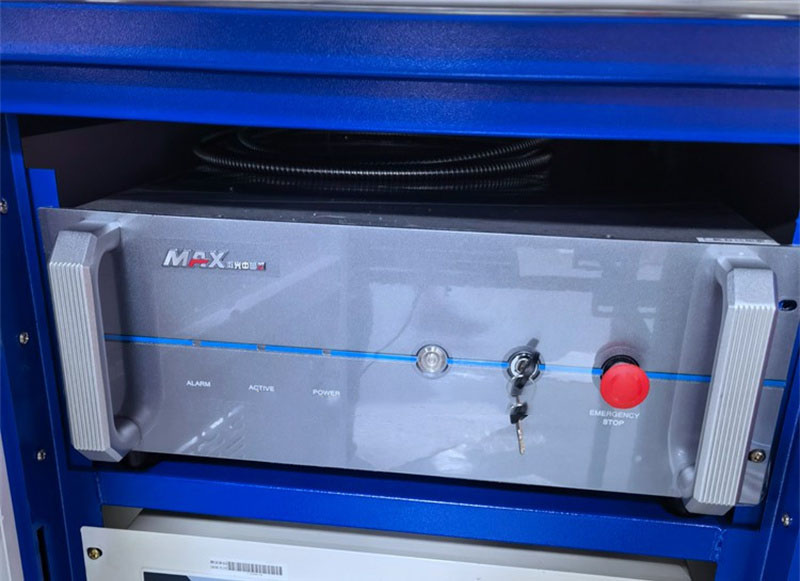

HW welding head HW control system Auto wire feeder for free

WSX/JPT optional usually coperate with laser head

Laser power Water chiller Comes with a variety of nozzles

パラメーター

モデル | LXW-1000 / 1500 / 2000W |

レーザー出力 | 1000/1500 / 2000W |

中心波長 | 1070 + -5nm |

レーザー周波数 | 50Hz〜5KHz |

作業パターン | 連続 |

電力需要 | AC220V |

出力ファイバ長 | 5/10 / 15m(オプション) |

冷却方法 | 水冷 |

寸法 | 1150 * 760 * 1370mm |

重さ | 275kg(約) |

冷却水温度 | 5-45℃ |

平均消費電力 | 2500/2800/3500 / 4000W |

レーザーエネルギーの安定性 | <2% |

空気湿度 | 10-90% |