序章

Break through the limitations of the original worktable,using swing welding head Any Angle welding, welding seam width adjustable, replace the traditional argon arc welding, Electric welding process, simple operation no need for welding certificate.

技術的パラメータ

Model.No | DTW-500W | DTW-1000W | DTW-1500W | DTW-2000W |

Operating Mode | Continuous/Modulation | |||

レーザー波長 | ±2% | |||

Power Requirements | 220V | 220V/380V | 220V/380V | 220V/380V |

Machine Power | ≤5KW | ≤7KW | ≤9KW | ≤11KW |

Operating Environment Temperature Range | 15〜35℃ | |||

Working Environment Humidity Range | <70% No Condensation | |||

Welding Thickness Range | 0.5-0.8MM | |||

Welding Line Requirements | ≤0.5mm | |||

溶接速度 | 0-120mm / s | |||

マシンサイズ | 1190×1100×650mm | |||

Laser cutting sample

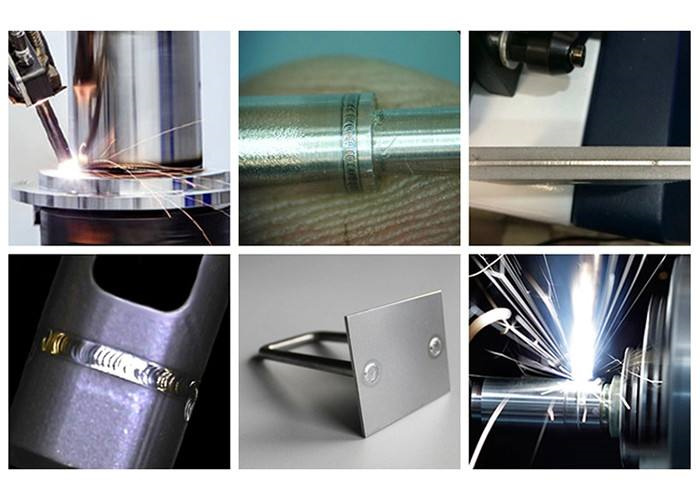

✦Applicable Materials: Leapion laser welding machine Application in Stainless steel, Carbon steel, Aluminum, Copper materials, etc.

特徴

Hand-held welding gun operating mode, can be welded to any angle of any part of the work piece.

Hand-held welded head is equipped with 10 m fiber, flexible and convenient can achieve outdoor welding.

Applicable to various complex welds, spot welding of various devices.

操作が簡単

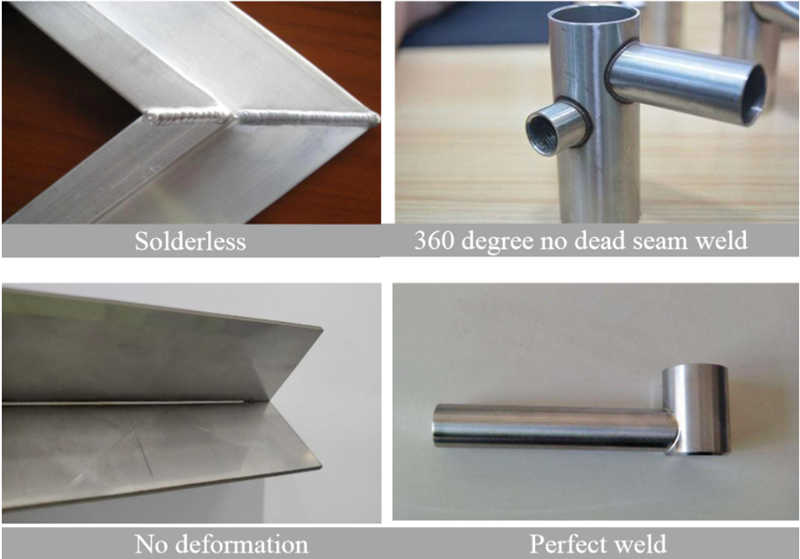

Simple and easy to operate, no deformation of the welding seam, stable laser output to ensure welding consistency, high power density after laser focusing, fast speed, great depth and small deformation, 360-degree micro-welding.

美しい溶接プロセス

元のワークベンチの制限を打ち破り、あらゆる種類の複雑な溶接シームに適しており、ワークピースの任意の部分を任意の角度で簡単に溶接できます。人間味のある設計と技術のアップグレードにより、美しい溶接シームを溶接できます。

小さなボディ、効率的な溶接

The welding speed of laser welding machine is 3-10 times that of traditional argon arc welding and plasma welding. The welding heat affected area is small, and it will not cause problems such as deformation, blackening, traces on the back of the joint construction, and the welding depth is large, the melting is sufficient, and the welding is firm.

デュアルドライブハンドヘルドスイングレーザー溶接ヘッド

さまざまな溶接ニーズを満たすために、6つの溶接モードと複数の溶接ノズルがあります。安全センサー機能を備えており、金属に触れた後にレーザーを放射し、金属が取り外されると自動的に光をロックします。スパイラルジッター機能、溶接幅の調整が可能で、溶接能力が大幅に向上します。

360°デッドアングルマイクロ溶接なし

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned, and is applied to micro and small workpieces that are automatically produced in large quantities. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, stitch welding, tailor welding, sealing welding, etc. High aspect ratio, small weld width, small heat aff